Collection: Brakes

Carbotech Performance Brakes

Friction materials have evolved significantly over the years. Brake pads were originally made with organic ingredients such as asbestos and carbon, held together by a strong resin. Most brake pads sold today are considered semi-metallic, semi-metallic brake pads use brass, copper, and steel wool shavings held together by a resin. Unfortunately, the main drawback about the use of steel strands, iron, graphite, and small amounts of filer and friction modifiers (used to provide strength and conduct heat away from the rotors) is that the metal shavings and iron must rub against steel rotors every time the brakes are applied. This generates more noise and is a lot more abrasive on the rotors. It also creates corrosive dust that can damage your braking system as well as the paint on your wheels and car.

At Carbotech, we felt these kinds of friction materials were not the best solution, and we decided to develop something that was better in performance and better for the entire braking system – a Ceramic Kevlar-based compound.

Friction materials that contain Ceramic Kevlar formulations have become recognized for their desirable blend of traits. This allows the Ceramic Kevlar pads to handle higher brake temperatures with less heat fade, and provide faster recovery after heavy braking. It also reduces brake dust and makes wheel maintenance easier!

Ceramic Kevlar compounds extend brake life compared to most other semi-metallic and organic materials, and at the same time they outlast other premium pad materials by a significant margin, without compromising in noise control, pad life, and all around braking performance.

Choosing the Correct Compound

-

AX6 - The AX6™ is specifically engineered for Autocross applications. A high torque brake compound delivering reliable and consistent performance over a very wide operating temperature range of 50°F to 1000°F + (10°C to 537°C+). The advanced compound matrix provides an excellent initial bite, high coefficient of friction at lower temperatures along with very progressive brake modulation and release characteristics. NOT FOR STREET USE!

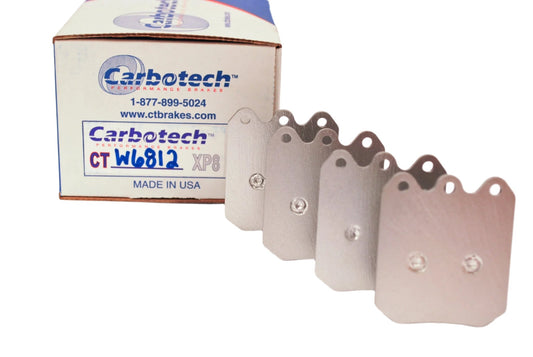

- XP8 - A high torque brake compound with a wide operating temperature range of 200°F-1250°F+ (93°C to 676°C+). Carbotech™ XP8™ is the first of our racing compounds. It provides good initial bite at race temperatures, high coefficient of friction, excellent modulation and release characteristics. XP8™ offers extremely high fade resistance and is very rotor friendly. It’s perfect for track day use with any tire. NOT FOR STREET USE!

- XP10 - When Carbotech™ unleashed the XP10™ to the general public it immediately gathered multiple regional, divisional, and national championships. The XP10™ has a very strong initial bite with a coefficient of friction and rotor friendliness unmatched in the industry. Fade resistance is in excess of 1475°F (801°C). XP10™ still maintains the highly praised release, excellent modulation and rotor friendliness that have made all Carbotech™ compounds so successful. NOT FOR STREET USE!

- XP12 - Another highly successful XP™ series compound with an excellent initial bite, torque and fade resistance over and above the XP10™ compound. XP12™ has temperature range of 250°F to 1850°F+ (121°C to 1010°C+). The XP12™ has that excellent Carbotech™ release and modulation that has made all other Carbotech™ compounds so successful. The XP12™ is more rotor aggressive than XP10™, but compared to the competition the XP12™ is still very rotor friendly. NOT FOR STREET USE!

PFC Brakes

- 97 - No info from PFC

-

11 - 11 compound is a new generation sprint and medium distance friction providing the ultimate in control, with superior disc conditioning. 11 compound was developed from the 01 compound with improved bite, modulation, and release characteristics. Good fade resistance & easy control. It is ultra-smooth and developed to reduce wheel locking at the end of a stop. For many applications, 11 will replace the venerable 01 compound.

- 13 - 13 compound is a new generation of ultimate high bite-high friction. 13 compound has been developed with increased bite, modulation, with superior disc conditioning and release characteristics for exceptional control. Ultra-smooth and great for tracks with high grip or high downforce cars. It is the ultimate combination of high bite and infinite control. Ideal use where high bite in the first third of the stop is desired. 13’s wear is on a par with PFC’s legendary 01 compound and will operate at higher temperatures if called to. 13 has a very high threshold for fade resistance. Out of all the high bite, high torque pads on the market 13 has shown to have one of the lowest taper wear in a properly designed race caliper.

- 39 - 39 compound is our newest choice for sprint and semi-endurance races in GT, TCR, NASCAR or rally tarmac/gravel. 39 has a high initial bite and the highest average torque of any PFC compound. Recommended for high downforce and severe environments. Very good retardation. Release and modulation characteristics are its best qualities, providing excellent control to the drivers, and avoiding lock-up. There is virtually no torque rise with temperature. A very positive and firm pedal when braking is another of its advantages. 39 offers excellent wear, better than 13, 15 or 333. Compound 39 is designed to handle the most severe applications. The winner’s choice!

Cobalt Friction

Cobalt Friction Technologies, Inc. is a leading developer & manufacturer of friction compounds for high-performance and professional motorsport disc brake applications. With our industry-leading range of race-proven XR-Series Carbon-Ceramic materials, Cobalt has a solution to meet your most demanding performance requirements, while always exceeding your expectations with superior technical and race engineering support.

Wilwood

BP compound SmartPad numbered series represents the latest compounds developed through Wilwood research. Used by top racers in all auto racing genres, they also come standard in most kits for street use. Four different formulas offer increasingly aggressive friction and tolerance to high temperature, from BP-10 for spirited street use to BP-40 for extremely demanding racing competition. Multiple friction options allow users to optimize brake response to track conditions and weather. Compatible with all iron, steel, stainless, and titanium rotors within their intended temperature ranges.

- BP-40 X-High Friction & High Temperature

- Aggressive high friction, fade-resistant, long-wearing race only formula for high-heat applications.

- Predictable and linear response with excellent pedal modulation and feel, start-to-finish.

- Asphalt oval tracks, road courses, extreme-duty dirt, and all types of off-road competition.

- BP-30 High Temperature & Friction

- High friction, high temp, extra-long wearing, fade resistant race-only formula designed for hard braking endurance racing.

- Exceptional pedal modulation and feel, start-to-finish.

- Road racing, asphalt short track, high grip or downforce cars with extreme hard braking and sustained high-heat cycles.

- BP-20 Med-High Temperature & Friction

- A true dual-sport performance compound providing clean and quiet driving on the street, with an expanded temperature and friction range for competition.

- Upgrade pad for our bolt-on brake kits for autocross, track events, and heavier weight, high-speed drag cars.

- Intermediate level dirt track use on limited tire, open wheel modifieds, and all types of hobby class racing.

- BP-10 Low-Med Temperature & Friction

- Baseline pad in Wilwood bolt-on brake kits for hot rods, muscle cars, and most street and drag strip applications.

- Light dusting, quiet engagement pads with increased friction, response, and an extended temperature range with higher fade resistance over OE-type compounds.

- Gradual response pad for lighter duty dirt track categories, especially in marginal traction

-

Carbotech XP12 Brake Pad (Pre-Bed Option) | Legend Wilwood Caliper

Regular price From $178.00 USDRegular priceUnit price / per -

Carbotech XP10 Brake Pad (Pre-Bed Option) | Legend Wilwood Caliper

Regular price From $171.00 USDRegular priceUnit price / per -

Carbotech XP8 Brake Pad (Pre-Bed Option) | Legend Wilwood Caliper

Regular price From $164.00 USDRegular priceUnit price / per -

Carbotech AX6 Brake Pad | Legend Wilwood Caliper

Regular price From $158.00 USDRegular priceUnit price / per -

PFC Brakes 39 Compound Brake Pad | Legend Wilwood Caliper

Regular price $148.47 USDRegular priceUnit price / per -

PFC Brakes 13 Compound Brake Pad | Legend Wilwood Caliper

Regular price $148.47 USDRegular priceUnit price / per -

PFC Brakes 11 Compound Brake Pad | Legend Wilwood Caliper

Regular price $148.47 USDRegular priceUnit price / per -

PFC Brakes 97 Compound Brake Pad | Legend Wilwood Caliper

Regular price $148.47 USDRegular priceUnit price / per -

Cobalt #2 Brake Pad | Legend Wilwood Caliper

Regular price $161.61 USDRegular priceUnit price / per -

Cobalt #3 Brake Pad | Legend Wilwood Caliper

Regular price $161.61 USDRegular priceUnit price / per -

Cobalt #4 Brake Pad | Legend Wilwood Caliper

Regular price $161.61 USDRegular priceUnit price / per -

Cobalt #5 Brake Pad | Legend Wilwood Caliper

Regular price $161.61 USDRegular priceUnit price / per -

Cobalt #6 Brake Pad | Legend Wilwood Caliper

Regular price $161.61 USDRegular priceUnit price / per -

Legend Wilwood Brake Pad BP-10

Regular price $59.26 USDRegular priceUnit price / per -

Legend Wilwood Brake Pad BP-20

Regular price $105.10 USDRegular priceUnit price / per -

Legend Wilwood Brake Pad BP-30

Regular price $124.82 USDRegular priceUnit price / per